Offshore casting of metal products in China presents an array of manufacturing issues that will directly affect profits if not properly managed. In fact, our 100% satisfaction guarantee says it all. We are fully capable of managing in-house, the everyday difficulties of doing business in China. We have the same ability to supply our customers with the option of the same products from overseas as they would find domestically. Over the past 15 years, G&W Foundry has developed solid and secure relationships with overseas foundries. The different grades of gray iron and ductile iron have various properties depending on the application of the casting to best suit the customers’ needs.

G&W Foundry manufactures machine tool castings such as machined tools, milling machines, lathes, grinding machines, and presses that are made from gray cast iron and ductile iron.

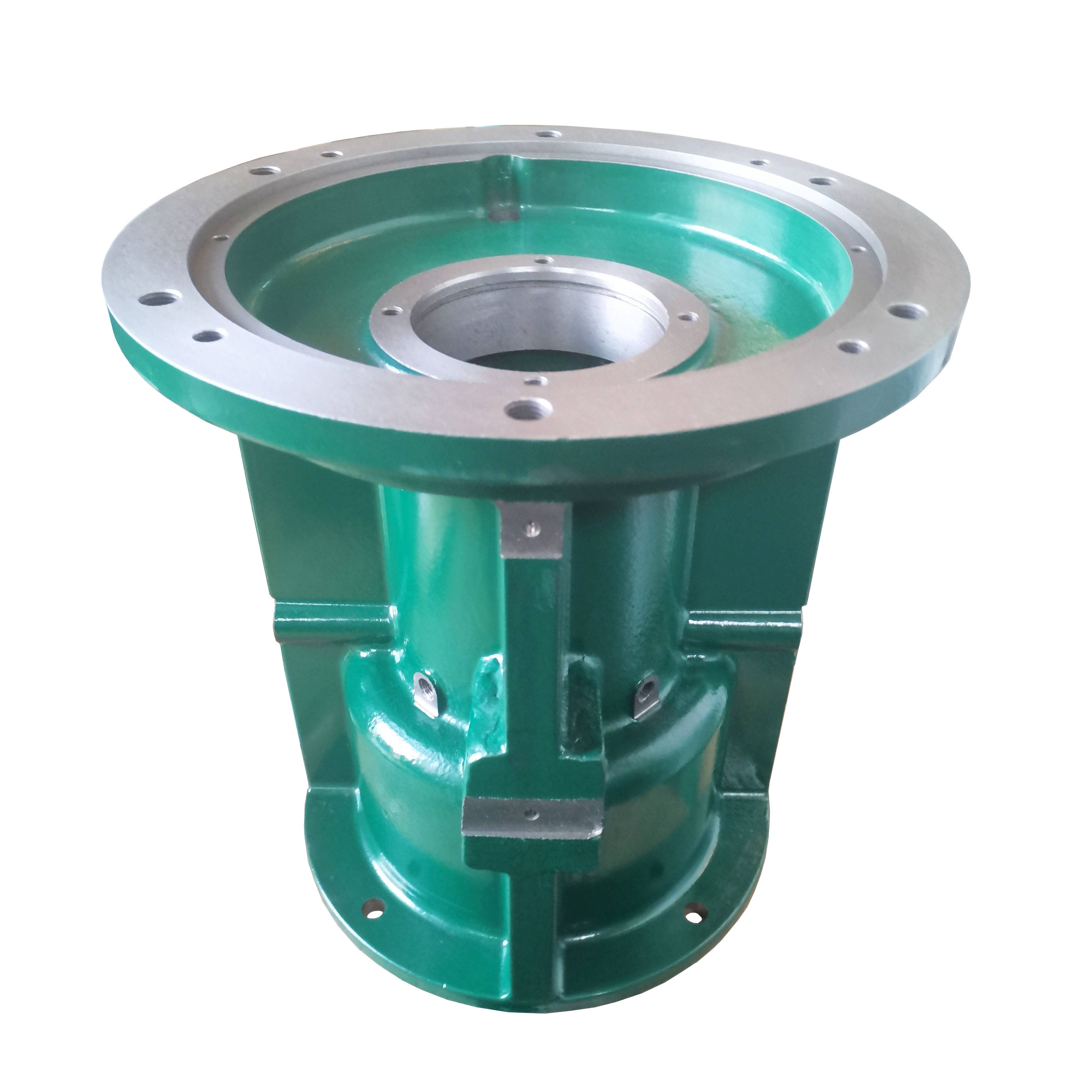

G&W Foundry is a global supply chain management company, with iron and metal foundry partners who manufacture in grey ductile, grey iron and light mental parts of aluminum, brass and alloys. We provide custom-fit solutions for our client’s requirements. Today, cast iron is found in almost all durable goods and machinery. The most predominant metals used in castings are iron, aluminum, steel and copper-base alloys. Metal casting is one of the oldest and most common casting processes. Iron Castings is still a large portion of what G&W produces today, domestic and offshore for a wide variety of different industries. When G&W Foundry was founded back in 1932, we produced mainly iron castings specializing in stoves and spare parts. While Green Sand is the most commonly used, no bake will produce a nicer surface finish that may be more attractive to the eye depending on your application. G&W Foundry primarily uses the Sand Casting process in our production of ductile iron castings along with other grades of metal castings. Sand Castings are poured at 2600 degrees Fahrenheit and are an inexpensive and efficient casting option. Sand Casting is the casting process that’s characterized by the use of sand as the mold material. We have the ability to produce castings in all shapes and sizes weighing as little as 1 ounce to 30,000 pounds. Our investment casting products can be utilized in a broad range of industries.G&W Foundry specializes in all types of metal castings from aluminum castings, bronze castings, iron casting, to stainless steel casting.

#China custom iron casting foundry manufacturer professional#

Pintejin professional investment castings machining involves CNC metal parts manufacturing,wire cutting and some difficult materials.

With the help of high-level technology and efficient equipment, as well as rigorous attitude, we passed the ISO9001:2015 quality certification, which supports the long-term development of Pintejin steel investment casting services, aluminum investment casting services, stainless steel lost wax casting, titanium investment casting, brass investment casting, investment casting mold, investment casting china custom parts and service, etc. INVEST-CASTING.COM – As an hi tech investment castings ltd and china investment moulding shop, Pintejin foundry has been specialized in OEM precision investment castings,vacuum investment casting parts production and prototyping castings services China for over 30 years and always maintaining the highest standard in delivery speed and reliable quality of precision castings. The Investment Casting Process Of Metal Parts

0 kommentar(er)

0 kommentar(er)